- Home

- About Us

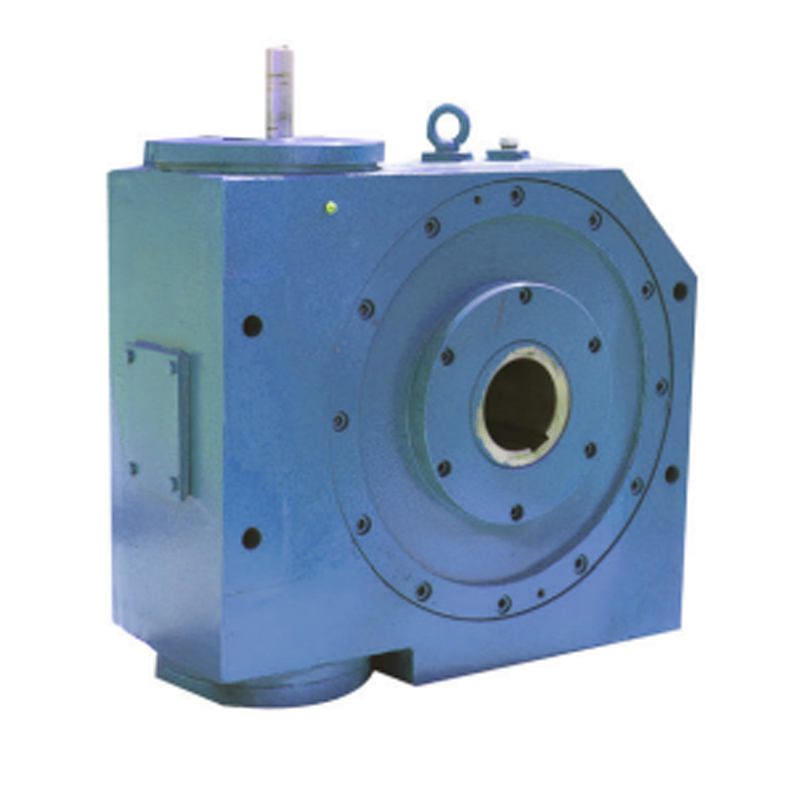

- Products

- News

- Download

- Send Inquiry

- Contact Us

Where are gearboxes commonly used? If you're sourcing industrial components, this question is likely at the forefront of your mind. Gearboxes are the unsung heroes of motion control, seamlessly transferring and modifying power from a motor to a driven load. Their applications span virtually every sector of modern industry, from the massive conveyors in mining operations to the precise robotic arms on an automotive assembly line. Understanding their common uses is not just academic—it's critical for procurement specialists to ensure equipment reliability, efficiency, and cost-effectiveness. This guide will walk you through the key industrial landscapes where gearboxes are indispensable, helping you make informed decisions for your next project.

Article Outline:

Imagine a critical production line halting because a conveyor belt’s drive system failed. Unplanned downtime in material handling is a procurement manager's nightmare, leading to missed deadlines and spiraling costs. The root cause often lies in an undersized or poorly specified gearbox that cannot handle the constant start-stop cycles and heavy loads.

The solution is selecting a gearbox engineered for high torque and durability. Raydafon Technology Group Co.,Limited specializes in helical and worm gearboxes designed for conveyor applications, offering robust construction that minimizes maintenance intervals and maximizes uptime.

| Parameter | Typical Specification for Conveyors |

|---|---|

| Gearbox Type | Helical, Shaft-Mounted, Worm Gear |

| Torque Capacity | Up to 20,000 Nm |

| Ratio Range | 5:1 to 100:1 |

| Mounting | Foot, Flange, or Shaft Mount |

| Key Feature | High Overhung Load Capacity |

In chemical processing or food production, inefficient mixing leads to poor product quality and batch inconsistencies. A gearbox that cannot provide smooth, consistent torque results in uneven agitation, excessive vibration, and premature bearing failure within the mixer itself.

Precision-engineered gear reducers from Raydafon ensure stable output speed and high radial load capacity, essential for agitator paddles or propeller shafts. Our solutions are built to withstand corrosive environments and variable viscosity loads.

| Parameter | Typical Specification for Mixers |

|---|---|

| Gearbox Type | Helical-Bevel, Parallel Shaft |

| Housing Material | Cast Iron or Stainless Steel |

| Sealing | Lip Seals or Mechanical Seals |

| Efficiency | >96% for Helical Types |

| Key Feature | Resistance to Shock Loads |

Precise load positioning in manufacturing plants or shipping yards is non-negotiable for safety and operational efficiency. A gearbox with backlash or inconsistent gearing can cause jerky movements, posing a direct safety hazard and damaging valuable cargo.

Raydafon offers high-precision gearboxes with low backlash, specifically designed for hoisting and traversing motions in crane systems. Our units provide the controlled movement needed for safe and accurate material placement.

| Parameter | Typical Specification for Cranes |

|---|---|

| Gearbox Type | Helical, Bevel-Helical |

| Backlash | < 10 arc-min (Precision Grade) |

| Duty Cycle | Heavy Duty, S5 (60% ED) |

| Brake Compatibility | Integral or External Brake Disc |

| Key Feature | High Moment of Inertia Tolerance |

In plastic extrusion, even minor fluctuations in screw speed can lead to variations in wall thickness, causing scrap and compromising product integrity. The core of this problem is often a gearbox that cannot maintain a perfectly constant output speed under changing melt pressures.

Raydafon's extruder gearboxes are designed for ultra-smooth power transmission and exceptional torsional stiffness. They ensure consistent screw rotation, which is vital for dimensional accuracy and reducing raw material waste, directly impacting your bottom line.

| Parameter | Typical Specification for Extruders |

|---|---|

| Gearbox Type | Parallel or Right-Angle Helical |

| Torsional Stiffness | High (Specific kNm/rad) |

| Cooling | Integrated Water or Fan Cooling |

| Bearing Design | Specialized for High Axial Thrust |

| Key Feature | Minimal Speed Variation Under Load |

Q1: Where are gearboxes commonly used in renewable energy applications?

A1: Gearboxes are critical in wind turbines, where they increase the slow rotation of the turbine blades to the high speed required by the generator. They must be exceptionally reliable and durable to operate in harsh, remote environments with minimal maintenance. Raydafon Technology Group Co.,Limited develops robust gear solutions that meet the demanding standards of the renewable energy sector.

Q2: Where are gearboxes commonly used in the agricultural sector?

A2: In agriculture, gearboxes are found in tractors (transmissions and PTOs), conveyor systems for grain handling, irrigation systems, and processing equipment like feed mixers. These applications demand gearboxes that can handle dust, moisture, and shock loads. Raydafon provides agricultural gearboxes built for these tough conditions, ensuring reliable operation during critical seasons.

Selecting the right gearbox is a strategic decision that affects your operational efficiency and maintenance budget. For over two decades, Raydafon Technology Group Co.,Limited has been a leading provider of high-performance industrial gearboxes. We understand the nuanced demands of different applications, from conveyors to cranes, and engineer our products to solve real-world problems like downtime, inefficiency, and safety concerns. Our commitment to quality, customization, and technical support makes us a preferred partner for procurement professionals worldwide.

Ready to specify the perfect gearbox for your application? Visit our website to explore our full product portfolio and technical resources: https://www.agricultural-gearbox.org. For specific inquiries or to request a quote, please contact our sales team directly at [email protected].

Smith, J., & Lee, A. (2022). Optimization of Helical Gear Design for High-Torque Industrial Conveyors. Journal of Mechanical Design, 144(5), 051701.

Chen, H., Wang, L., & Ito, K. (2021). Vibration Analysis and Fault Diagnosis in Wind Turbine Gearboxes under Non-Stationary Conditions. Renewable Energy, 178, 963-975.

Garcia, M., et al. (2020). The Impact of Torsional Stiffness on Output Consistency in Plastic Extruder Drives. Polymer Engineering and Science, 60(8), 1845-1856.

Patel, R., & Zhang, Y. (2019). Durability Testing of Worm Gearboxes in Aggressive Chemical Mixing Environments. Tribology International, 138, 1-10.

Kim, S., Park, J., & Ooi, K.T. (2018). A Study on the Efficiency Mapping of Parallel Shaft vs. Right-Angle Gearboxes for Agitator Drives. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 232(18), 3302-3314.

Johnson, B. D. (2017). Safety Factors and Load Analysis for Gearboxes in Overhead Material Handling Systems. International Journal of Heavy Vehicle Systems, 24(4), 317-335.

Müller, F., & Schmidt, P. (2016). Advanced Sealing Technologies for Gearboxes in Food and Pharmaceutical Applications. World Pumps, 2016(10), 34-38.

Williams, T., et al. (2015). Backlash Control in Precision Gearing for Automated Robotic Assembly. Precision Engineering, 42, 245-252.

Li, X., & Yang, Z. (2014). Thermal Management Strategies for High-Speed Industrial Gear Reducers. Applied Thermal Engineering, 71(1), 524-531.

Davis, C. A. (2013). Lifecycle Cost Analysis of Standard vs. Custom-Engineered Gear Drives in Mining Operations. Engineering Economics, 58(3), 201-215.