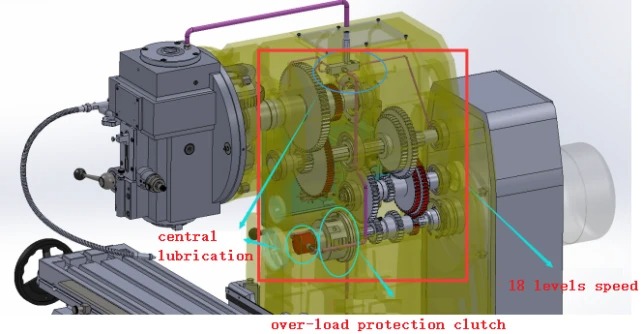

The WN600 Vertical CNC Knee-Type Milling Machine is a versatile metalworking machine that combines the features of a conventional

knee-type milling machine with the precision and automation of CNC technology.

- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us