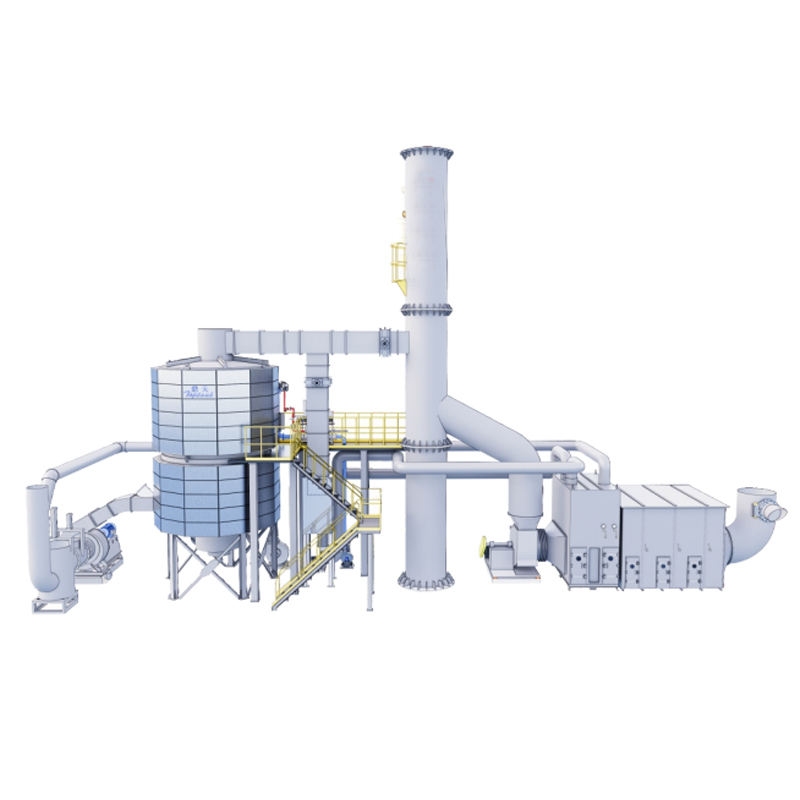

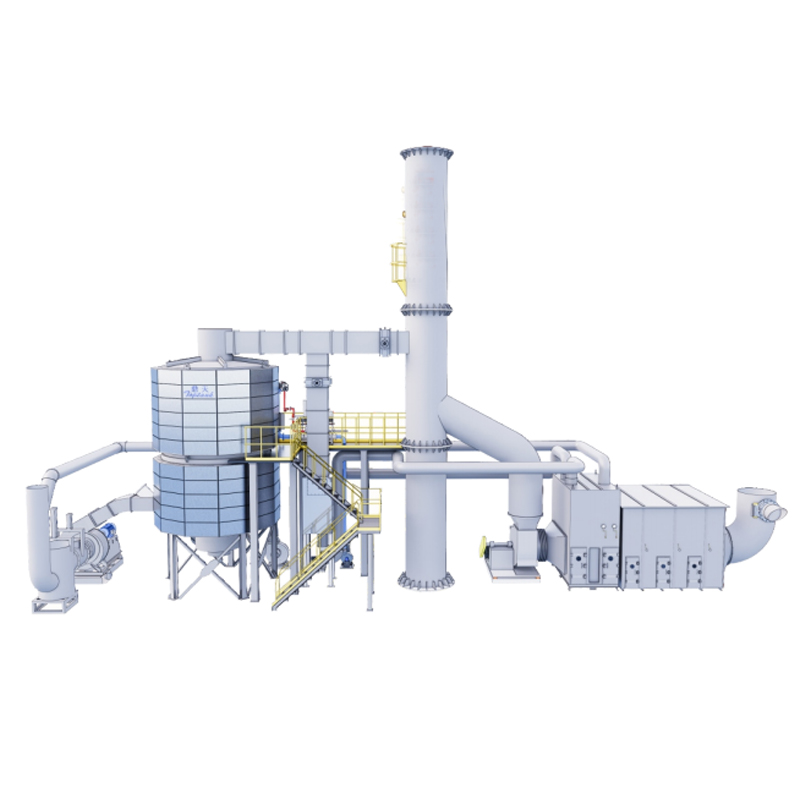

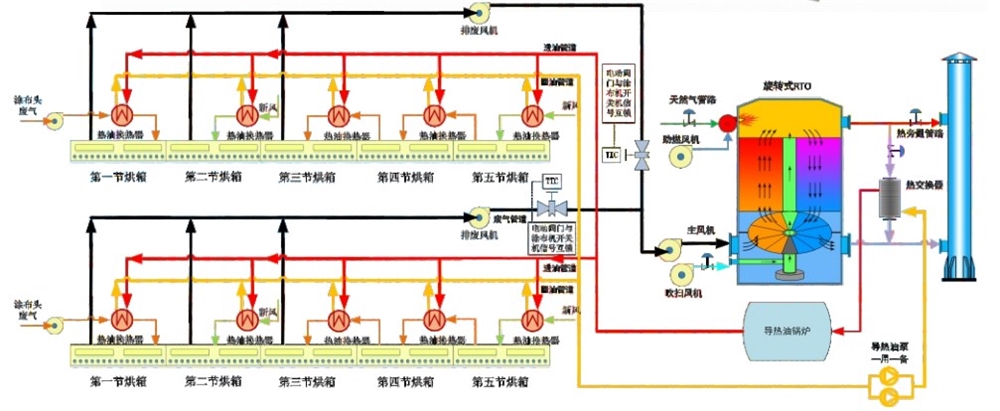

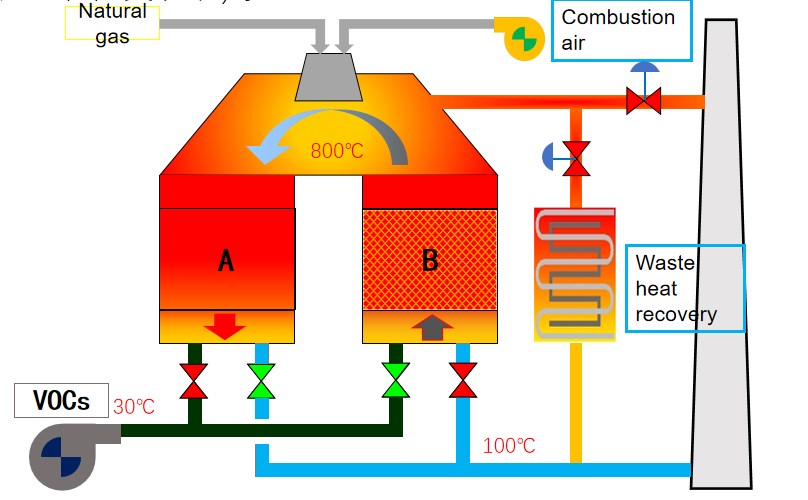

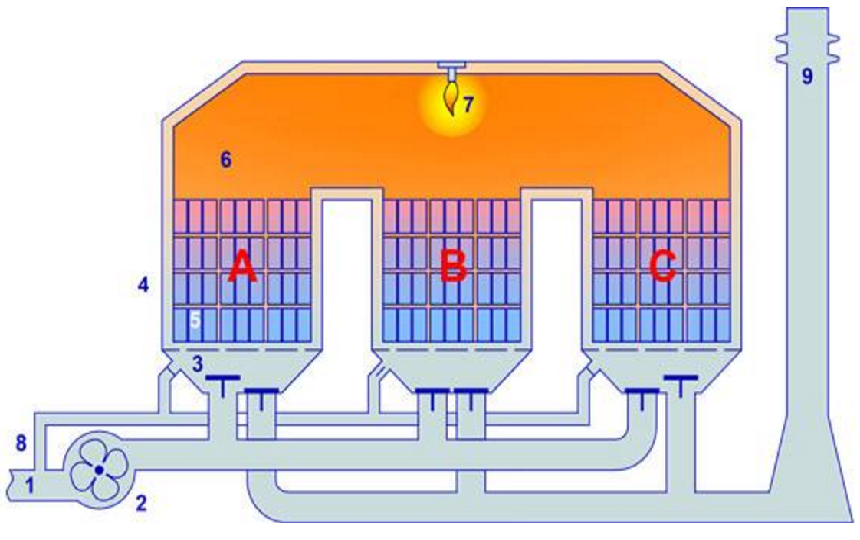

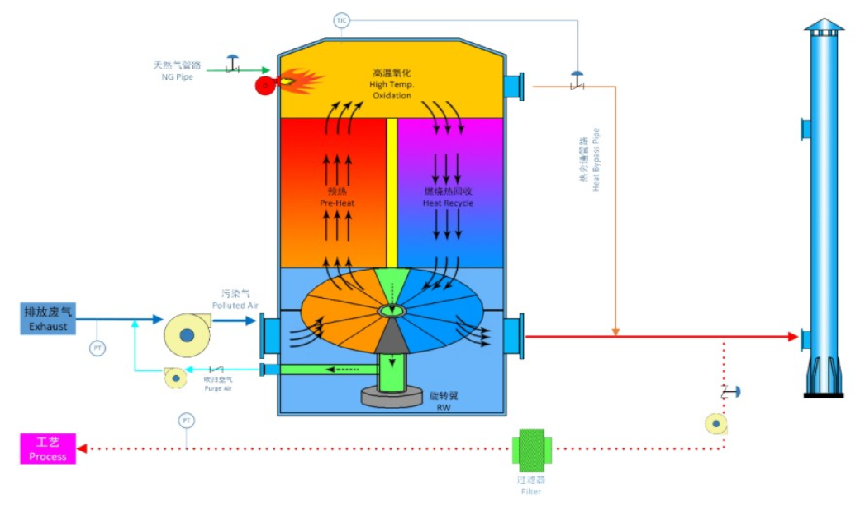

Using an RTO device to incinerate VOCS waste gas at high temperatures, achieving standard emissions. During the combustion of VOCS waste gas, a large amount of heat is released to maintain the reaction. When the concentration is high, waste heat recovery can also be carried out, achieving the goal of "environmental protection+energy conservation".

- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us