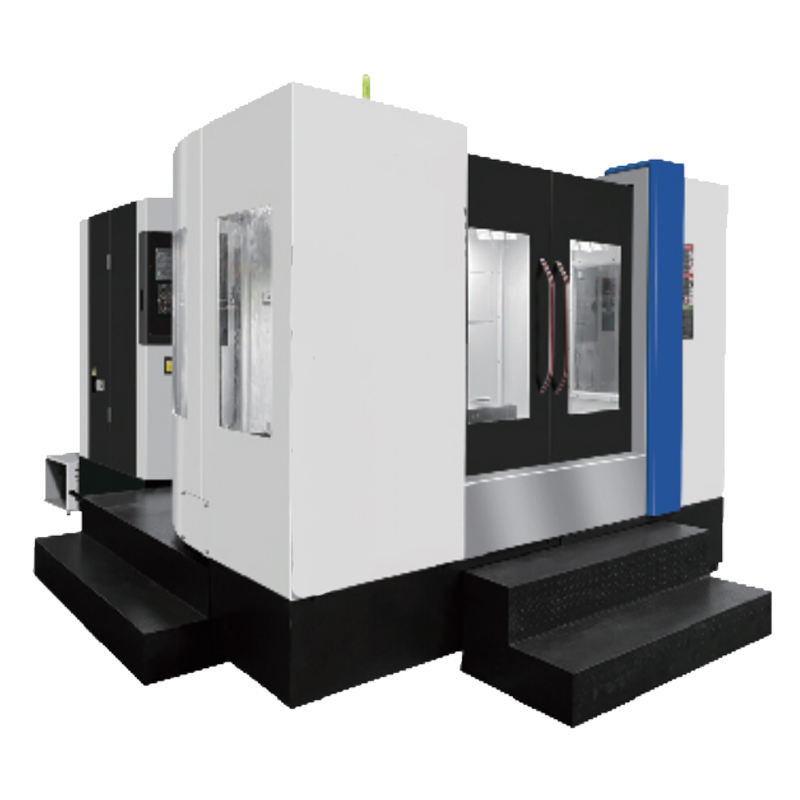

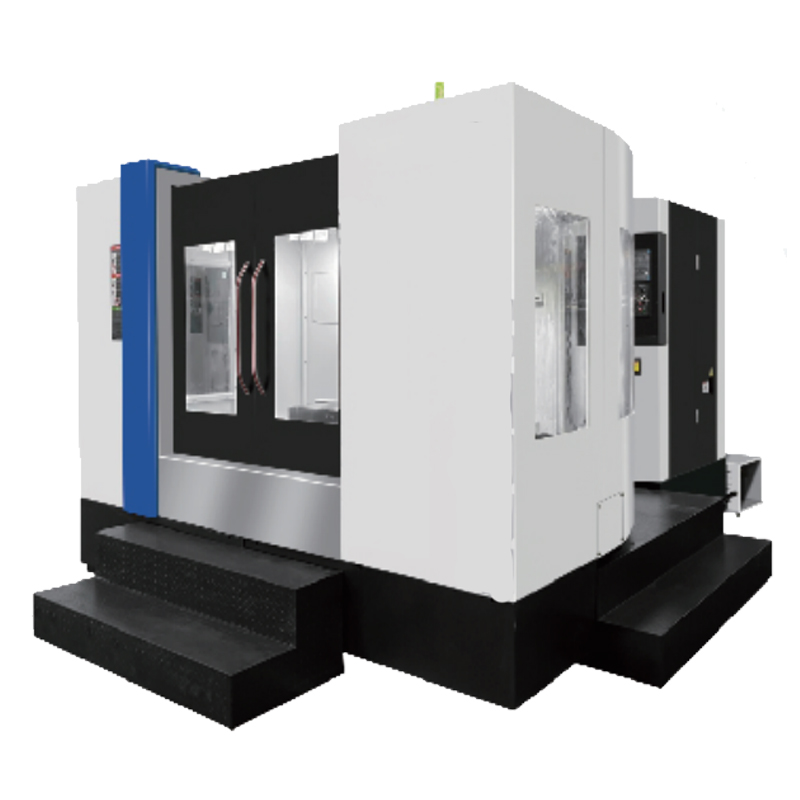

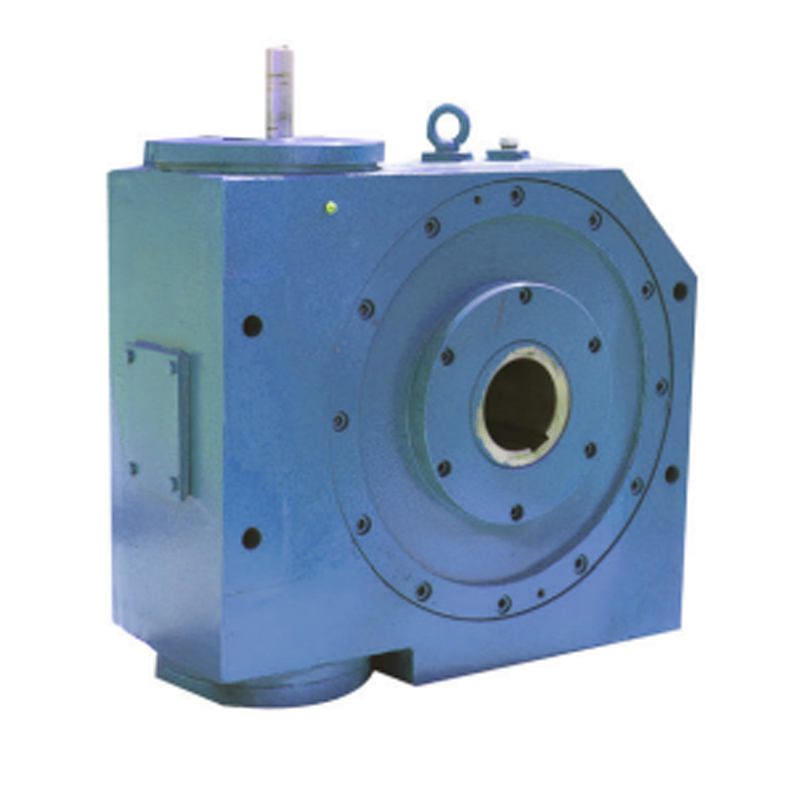

The gantry frame is paired with a dual axis turntable to achieve five axis and five sided machining. The dual axis turntables are all direct drive torque motors but not linked, allowing for positioning and machining at any position. The workbench size is 400. Specially suitable for the processing of polyhedral covers and shells of complex automotive chassis components.

Five axis linkage, high-speed and high-precision

Able to achieve positioning and processing at any position

Optimization of Machine Tool Performance