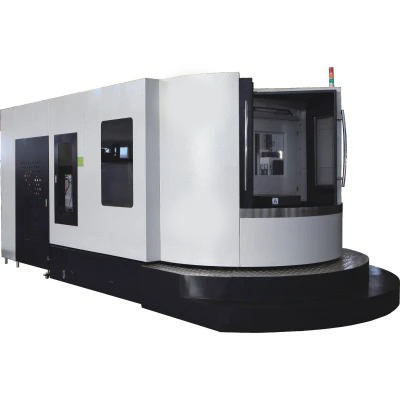

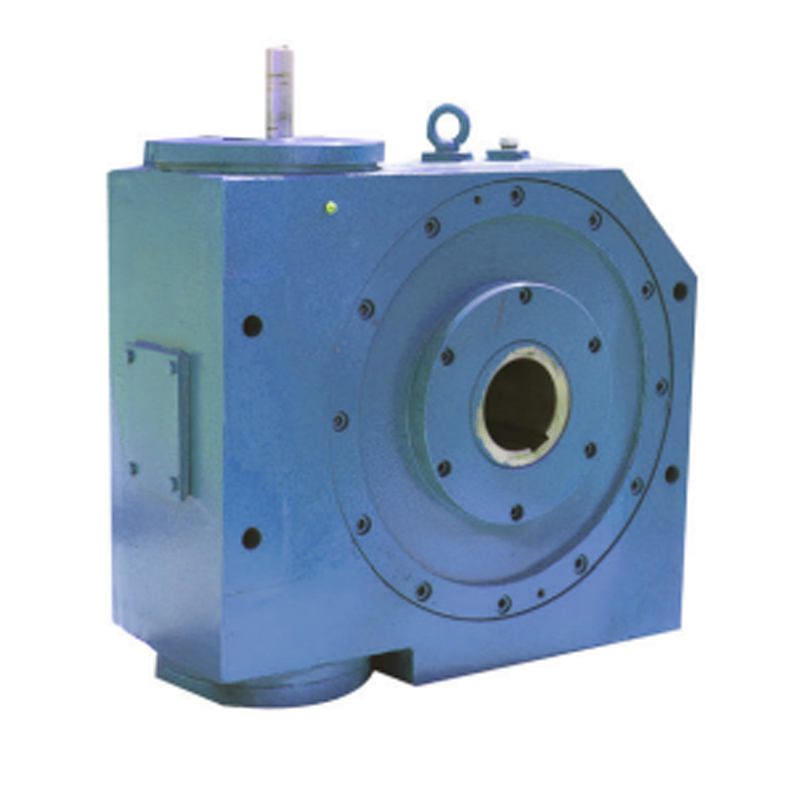

This series of column beam fixed double column machining centers adopts the international dynamic stiffness design concept to optimize the design of moving components based on the high stiffness, structural symmetry, and high stability of traditional double column machining. This series of machine tools has the characteristics of high torque and fast feedback, which can meet the needs of mechanical processing fields such as automobiles, molds, aviation, and industry. This series of machine tools mainly consists of components such as base, workbench, column, crossbeam, saddle, hydraulic system, lubrication system, cooling and filtering system, chip cutting device, CNC system, etc.The SP1540 Double Column Machining Center offers several advantages and finds wide application in various industries.Here are its key advantages and applications:1. High Precision Machining: The SP1540 provides exceptional precision and accuracy in machining operations. It is designed to meet the demands of industries that require tight tolerances and precise positioning, such as aerospace, automotive, and medical manufacturing.

2. Large Workpiece Machining: With its spacious working area, the SP1540 can accommodate large workpieces. It is suitable for industries that deal with oversized components, such as heavy machinery, construction equipment, and wind energy applications.

3. Heavy-Duty Machining: The robust double column structure of the SP1540 ensures stability and rigidity during heavy-duty machining tasks. It can handle tough materials like steel, stainless steel, and titanium, making it well-suited for industries such as energy, oil and gas, and heavy equipment manufacturing.

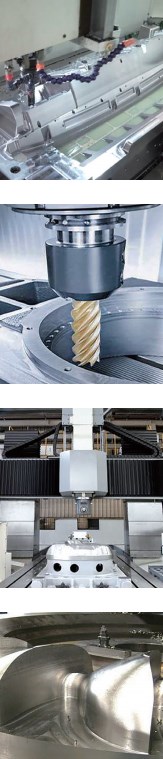

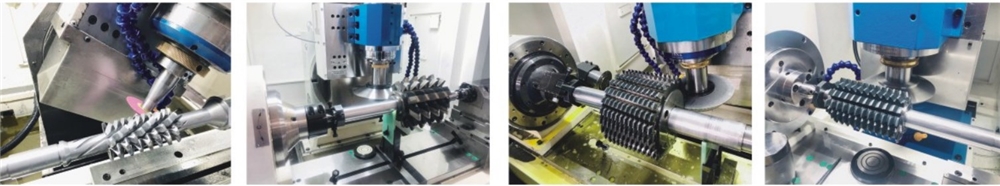

4. Multi-Axis Machining: The SP1540 supports multi-axis machining, including 3-axis, 4-axis, and 5-axis operations. This versatility allows for complex machining tasks, such as simultaneous milling, drilling, and contouring, making it suitable for industries that require intricate part geometries.

5. High-Speed Machining: Equipped with a high-speed spindle and advanced control systems, the SP1540 enables high-speed machining operations. It is beneficial for industries that demand efficient material removal rates and reduced cycle times, such as automotive, aerospace, and electronics manufacturing.

6. Efficient Tool Changing: The SP1540 features an automatic tool changer, allowing for quick and seamless tool changes. This feature enhances productivity by minimizing downtime and enabling continuous machining operations.

7. Versatile Applications: The SP1540 finds applications in various industries including aerospace, automotive, energy, mold and die, and general machining. It can handle a wide range of materials, from metals to composites, catering to diverse manufacturing needs.

8. Reliability and Durability: Built with high-quality components and a robust construction, the SP1540 offers reliable performance and long-term durability. It is designed to withstand demanding production environments, ensuring consistent results and minimizing maintenance requirements.

- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us