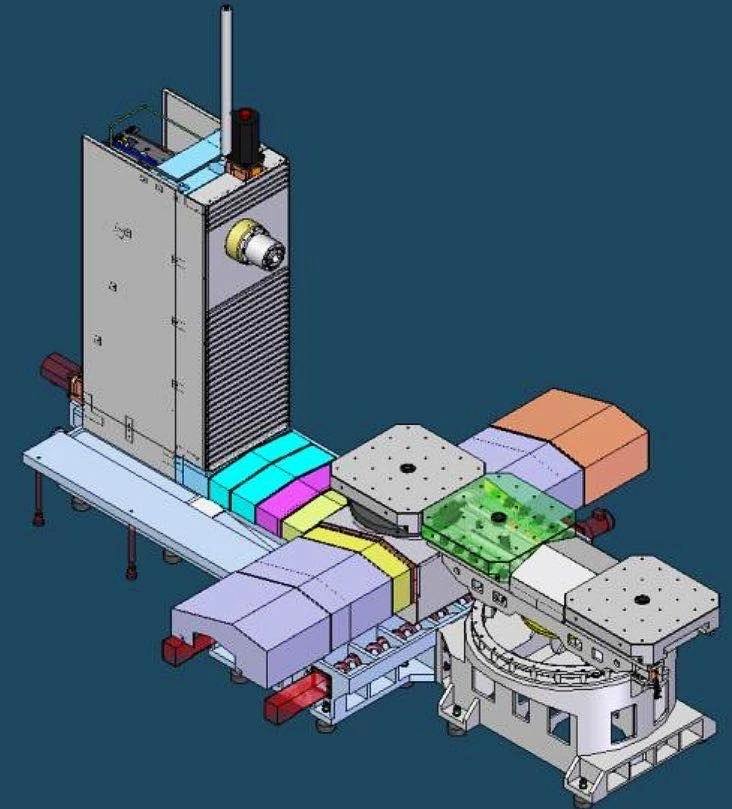

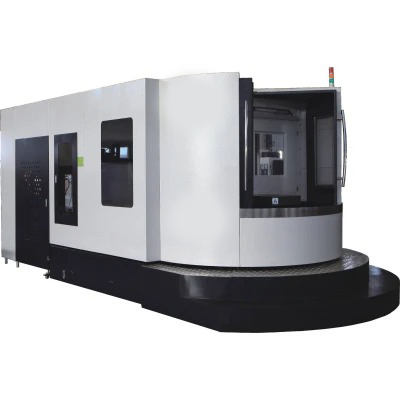

The HMC630P Horizontal Milling Machine is a versatile and high-performance machine tool used in various industries for efficient and precise milling operations.

Advantages:

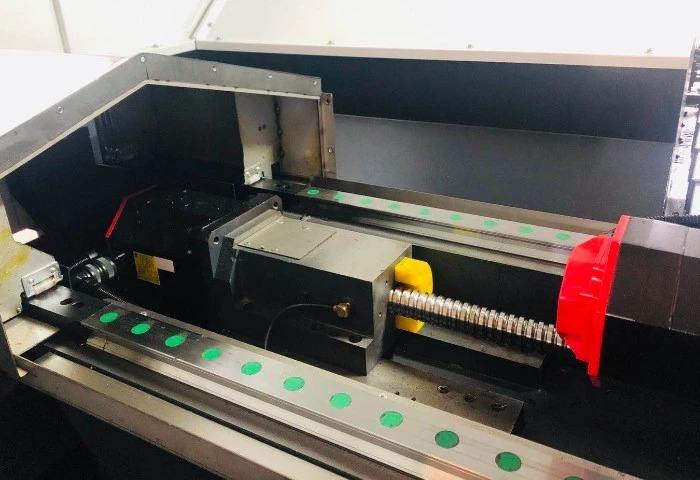

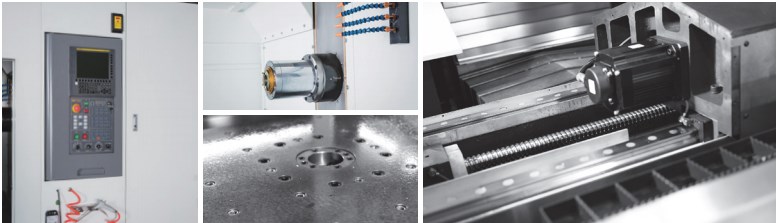

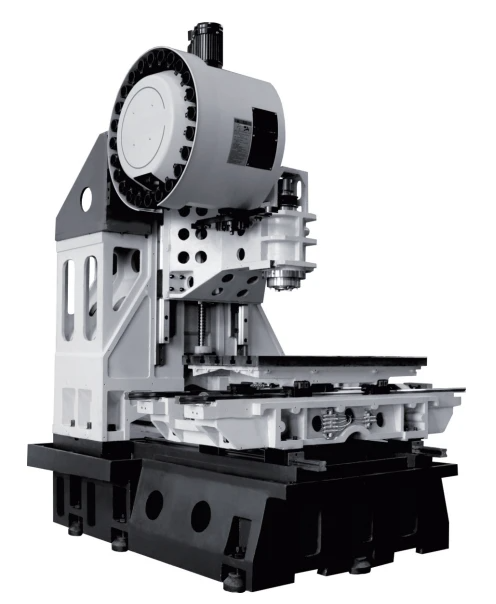

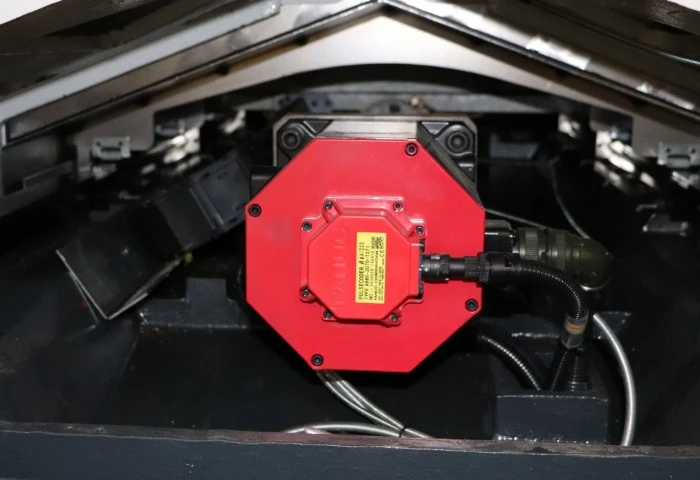

1. High Precision: The HMC630P offers exceptional precision and accuracy, ensuring tight tolerances and superior surface finishes for machined parts.

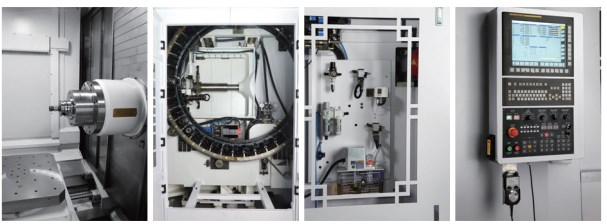

2. Rigidity and Stability: With its robust construction and rigid bed, the HMC630P provides excellent stability during heavy cutting operations, minimizing vibrations and ensuring consistent results.

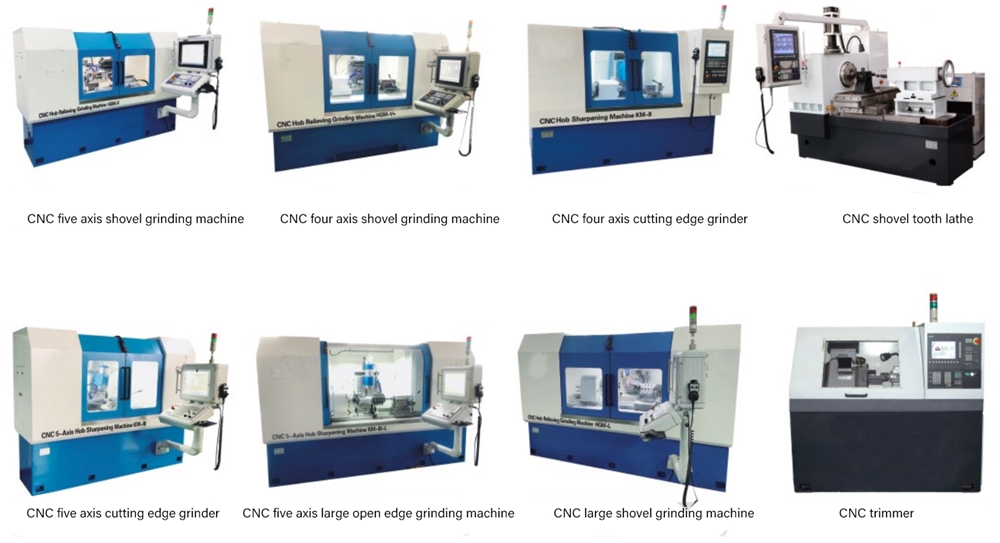

3. Versatility: This milling machine features multi-axis capabilities, allowing for complex machining tasks and accommodating a wide range of workpiece sizes and geometries.

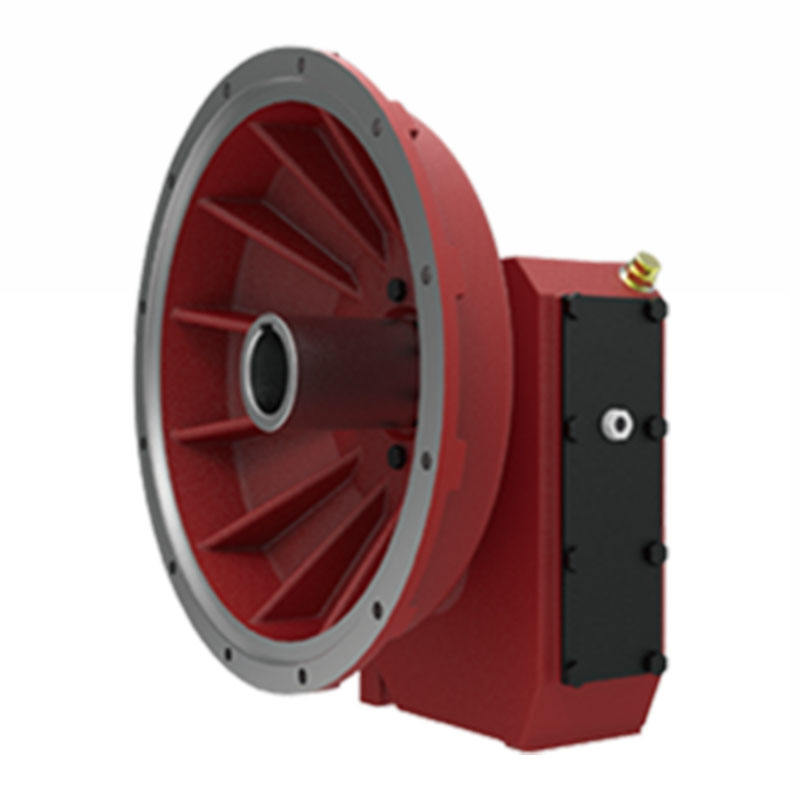

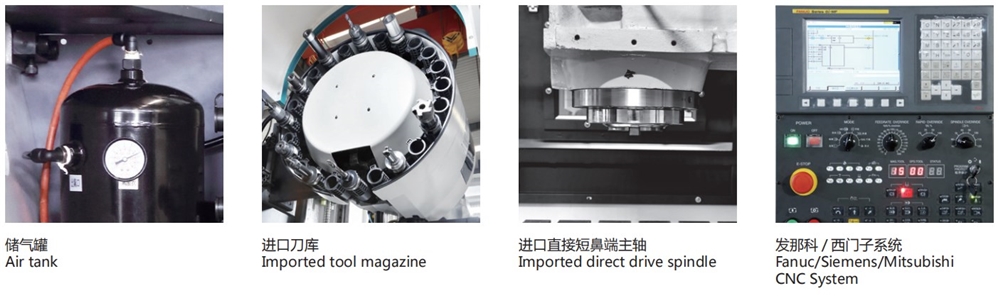

4. High Productivity: Equipped with a powerful spindle and a fast tool change system, the HMC630P enables efficient and rapid production, reducing cycle times and maximizing productivity.

5. Advanced Control System: The machine incorporates a user-friendly control interface, facilitating easy programming, operation, and monitoring of milling processes.

Applications:

The HMC630P Horizontal Milling Machine finds applications in various industries, including:

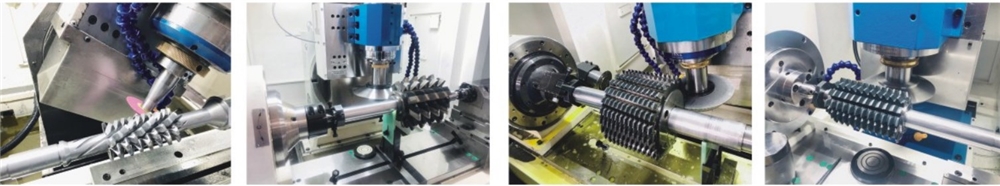

1. Automotive: It is used for milling engine blocks, transmission components, chassis parts, and other automotive components.

2. Aerospace: The HMC630P is employed to machine complex aerospace parts, such as aircraft structural components, landing gear parts, and turbine components.

3. Mold and Die Making: It is widely utilized for milling molds and dies used in plastic injection molding, die casting, and other molding processes.

4. General Machining: The HMC630P caters to a wide range of general milling applications, including milling, drilling, tapping, and contouring operations on various materials.

- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us