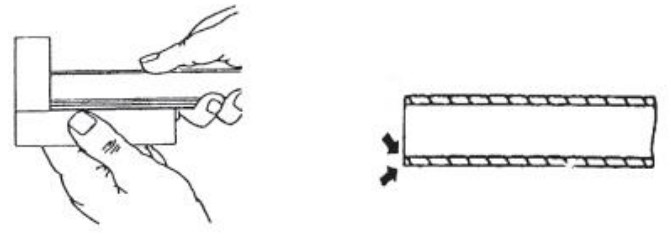

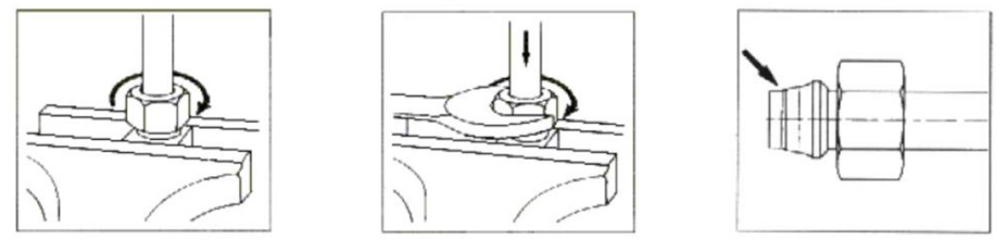

2. Lightly remove chips and particles from the inside and outside cut edges of tube. Bevel up to 0.2mm × 45 is permissible.

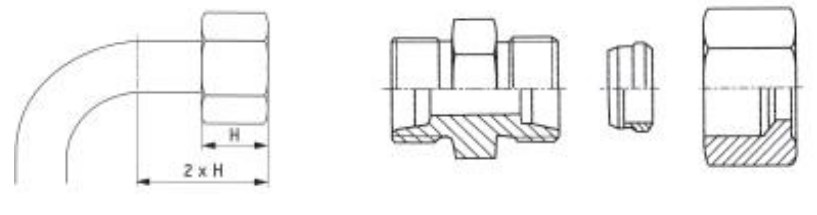

3. For tube bend, the minimum height from the straight pipe end to the bending radius must be at least twice the

height of the nut.

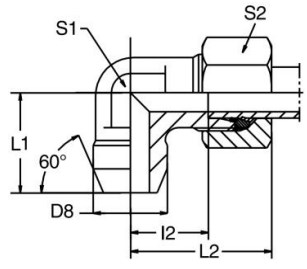

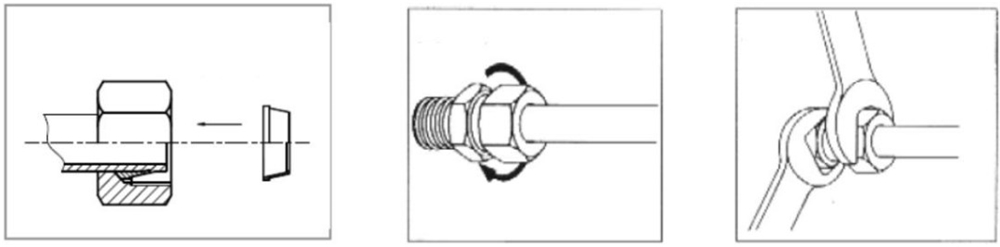

4. Lubricate thread and cone of the fitting body, ring and thread of nut.

- Home

- About Us

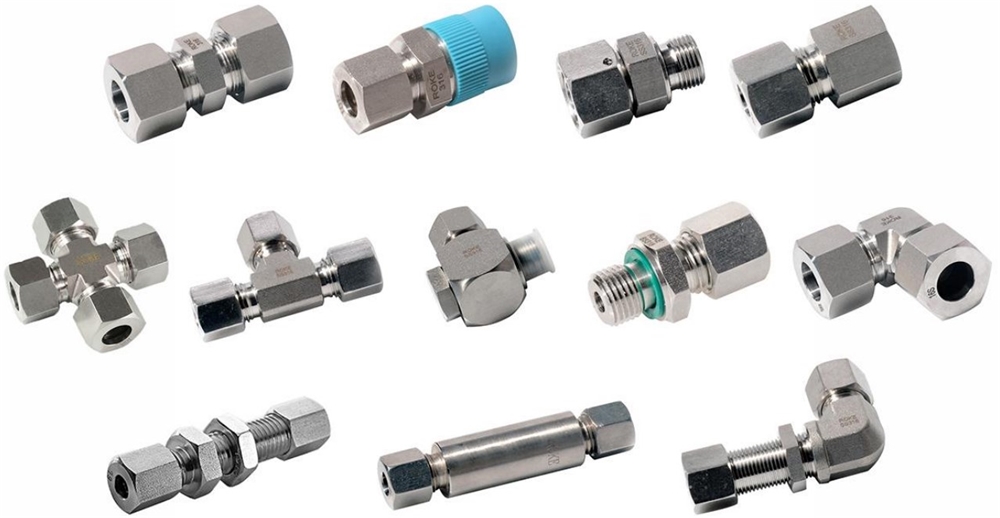

- Products

- News

- Download

- Send Inquiry

- Contact Us