- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us

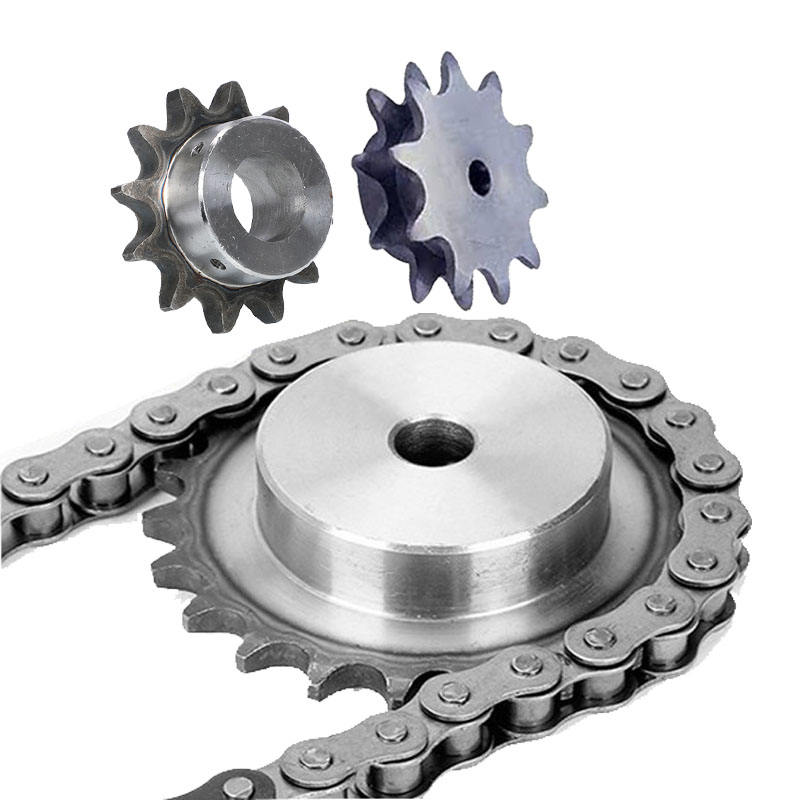

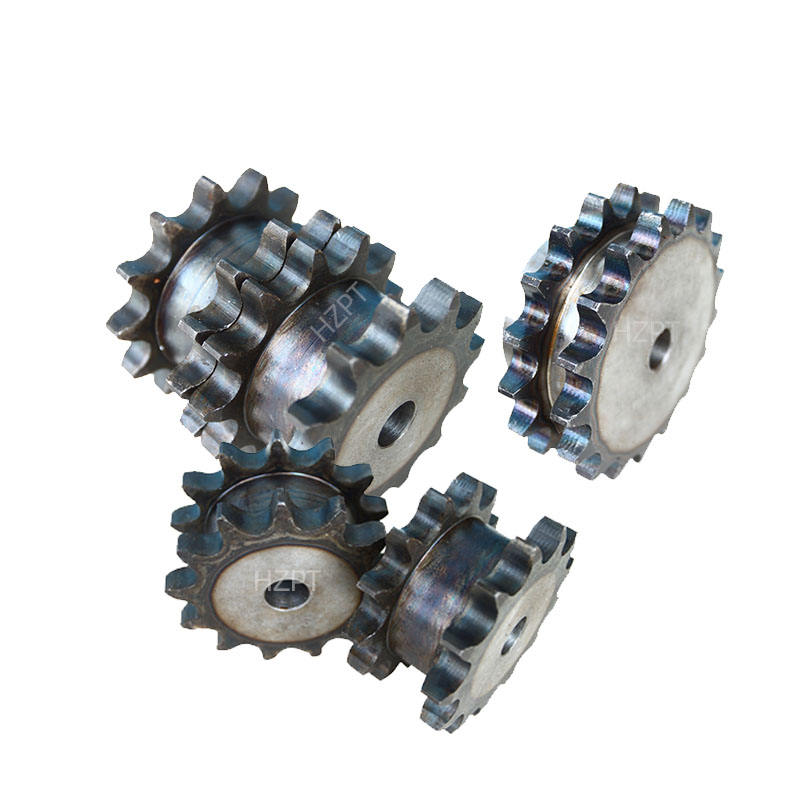

Sprockets are toothed wheels or profiled wheels that engage with chains, tracks, or other perforated materials. They are fundamental components in machinery, bicycles, automotive systems, and industrial equipment, designed to transmit rotary motion between two shafts where gears are unsuitable. Their precise engineering ensures efficient power transfer, minimal slippage, and durability under various operational conditions.

When selecting sprockets, understanding their technical parameters is crucial for optimal performance. Below is a detailed breakdown of common specifications:

| Parameter | Description | Typical Range |

|---|---|---|

| Bore Diameter | Inner hole size for shaft mounting | 0.5 inches to 6 inches |

| Outside Diameter | Overall diameter including teeth | 1 inch to 24 inches |

| Hub Length | Length of the central projection for stability | 0.5 inches to 4 inches |

| Weight | Varies by material and size | 0.1 lbs to 50 lbs |

Sprockets are versatile and used across industries:

What factors should I consider when choosing a sprocket?

Consider the application environment, load requirements, chain type, tooth count, pitch, material compatibility, and shaft size. Always match the sprocket specifications to the chain and operational conditions to avoid premature wear or failure.

How often should sprockets be replaced?

Replacement intervals depend on usage intensity, maintenance, and material. In high-wear environments, inspect every 3-6 months; for light use, annually. Signs for replacement include visible tooth wear, cracking, or chain slippage.

Can I use a sprocket with a different pitch than my chain?

No, mismatched pitches cause improper engagement, leading to accelerated wear, noise, and potential system failure. Always ensure the sprocket pitch exactly matches the chain pitch.

What maintenance do sprockets require?

Regular cleaning to remove debris, lubrication to reduce friction and wear, and periodic inspection for alignment and tooth damage. Use appropriate lubricants based on material and environment.

Are there silent sprockets available?

Yes, sprockets made from nylon or with specialized tooth profiles (e.g., helical designs) reduce noise. They are common in applications requiring quiet operation, such as office machinery or medical devices.

How do I calculate the speed ratio between two sprockets?

Divide the number of teeth on the driven sprocket by the number on the drive sprocket. For example, if the drive sprocket has 20 teeth and the driven has 40, the ratio is 2:1, meaning the driven shaft rotates half as fast but with doubled torque.

What is the difference between a sprocket and a gear?

Sprockets engage with chains or tracks, while gears mesh directly with other gears. Sprockets allow for greater distance between shafts and are less prone to slippage in dirty conditions, but gears offer higher precision and efficiency in close-quarters transmission.

Can sprockets be customized for specific needs?

Yes, manufacturers often provide custom options for tooth count, material, bore size, and special coatings (e.g., zinc plating for corrosion resistance). Provide detailed application requirements for tailored solutions.