- Home

- About Us

- Products

- News

- Download

- Send Inquiry

- Contact Us

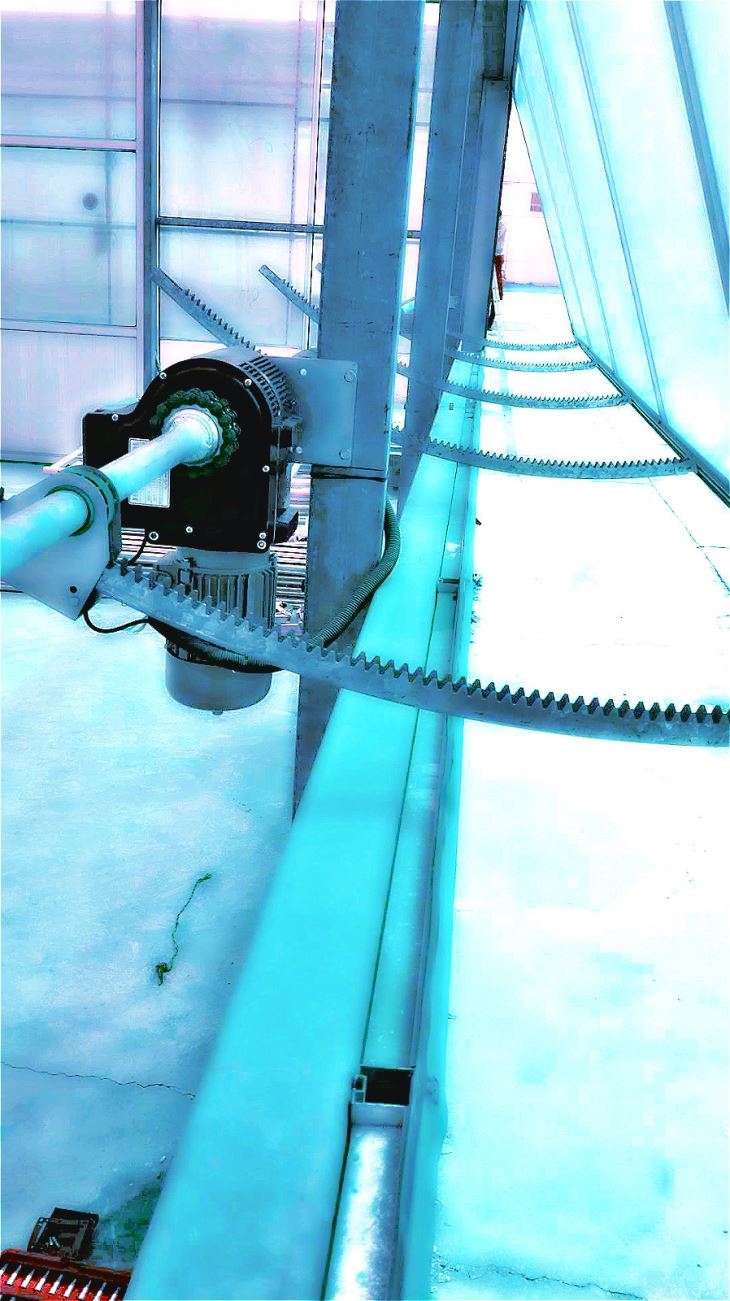

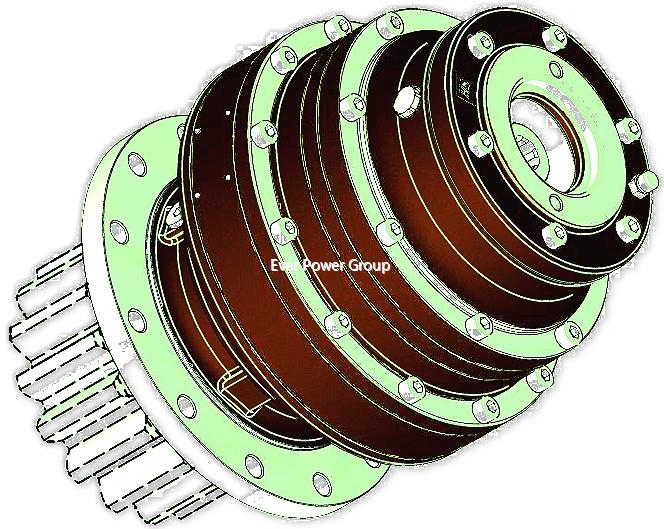

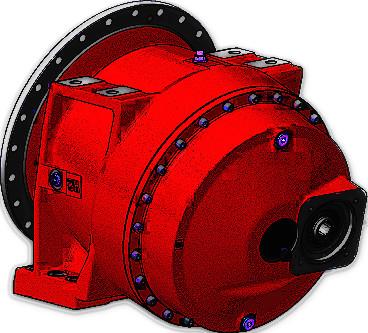

In mechanical engineering, a Gearbox is a crucial component used to transmit power from a prime mover, such as an engine or motor, to various driven parts by altering torque and speed. It consists of a set of gears enclosed in a housing, designed to provide efficient power transfer in numerous applications, including automotive, industrial machinery, and renewable energy systems.

Our gearbox is engineered with precision to meet high-performance standards. Below are the detailed specifications presented in lists and tables for clarity.

| Model Number | Ratio Range | Input Speed (RPM) | Output Speed (RPM) | Backlash (arcmin) | IP Rating |

|---|---|---|---|---|---|

| GBX-100 | 5:1 to 100:1 | Up to 3000 | 30 to 600 | <10 | IP65 |

| GBX-200 | 10:1 to 200:1 | Up to 1500 | 7.5 to 150 | <8 | IP66 |

| GBX-300 | 20:1 to 300:1 | Up to 1000 | 3.3 to 50 | <6 | IP67 |

What is the typical lifespan of a gearbox?

The lifespan depends on operating conditions, but with proper maintenance, our gearboxes can last over 50,000 hours. Factors like load, temperature, and lubrication intervals affect durability. Regular inspections and using recommended lubricants can extend service life significantly.

How do I select the right gearbox for my application?

Consider key parameters such as input power, torque requirements, speed ratio, mounting style, and environmental conditions (e.g., exposure to dust or moisture). Our GBX-100 model is ideal for light industrial use, while GBX-300 suits heavy-duty applications. Consulting our technical team for a customized solution is recommended.

What maintenance is required for a gearbox?

Maintenance includes periodic lubrication checks, oil changes every 10,000 hours or as per operating manual, inspection for leaks, and monitoring noise/vibration levels. Our gearboxes are designed for low maintenance, with sealed units requiring minimal intervention under normal conditions.

Can the gearbox be used in harsh environments?

Yes, our gearboxes feature high IP ratings (IP65 to IP67), making them resistant to dust, water, and extreme temperatures. Additional coatings and materials can be customized for corrosive or high-impact environments upon request.

What is the warranty period for your gearboxes?

We offer a standard warranty of 24 months from the date of purchase, covering defects in materials and workmanship. Extended warranty options are available for specific applications, subject to terms and conditions.

How does gearbox efficiency impact energy consumption?

Higher efficiency (95-98% in our models) reduces energy loss, leading to lower operating costs and improved sustainability. This is particularly important in continuous operations, where even a small efficiency gain can result in significant savings over time.

Are custom gear ratios available?

Yes, we provide custom gear ratios and configurations to meet unique application needs. This includes alterations in size, ratio, and mounting options. Contact our engineering team with your specifications for a tailored solution.

What safety features are incorporated?

Our gearboxes include overload protection, thermal sensors, and robust housing to prevent failures. Compliance with international standards like ISO and CE ensures safety and reliability in various industries.